TallKee Steel Structure

E-Mail:landy.sh137@gmail.com- K Span Machine

- ABM K Span Machine

- Arch Building Forming Machine

- Ultimate Building Machine

- Roll Forming Machine

- Sandwich Panel Forming Machine

- Purline Profile Roll Forming Machine

- Color Coated Steel Plate Forming Machine

- Roof Panel Roll Forming Machine

- Glazed Tile Roll Forming Machine

- Corrugated Sheet Roll Forming Machine

- Deck Floor Roll Forming Machine

- Guard Rail Roll Forming Machine

- Auxiliary Equipment

- Tube Bending Machine

- Plate Bending Machine

- Cutting Machine

- Slitting Machine

- Ridge Tile Forming Machine

- Window and Door Taping Machine

- Color Coated Steel Coil

- Polyurethane Painting Machine

- Low Pressure PU Foam Machine

- High Pressure PU Foam Machine

High Pressure PU Foam Machine

Features:

1. The high pressure PU foam machine adopts measure pump, so this machine has slow speed and high precision. Even if the temperature is changing, pressure and viscosity will not change then mixed proportion.

2. This steel construction machine has many advantages, especially having advanced pour point structure and others are reliable performance, convenient operation, and easy maintenance. With these advantages, this kind of high pressure polyurethane foam machine can be moved in the direction of front, back, left, right upper and below.

3. This machinery is also equipped with PLC to improve its automatic ability.

Application:

This high pressure polyurethane foam machine is used to produce horniness and semi-horniness, such as instrument plate, cold locker, active cold storage board, etc.

Technical Specification:

1) Main pump motor power: 15kW x 2

2) Mixing motor power: 0.55kW (installed inside A tank)

3) Hydraulic pump motor power: 2.2kW

4) Flux: 40-400kg per minute

5) Injecting time: 0.1-99.9s

6) Injecting pipe high pressure protected by pressure gauge with electric contact

7) Filters for Polyol and ISO glues: DN110 self-clean filter

8) Hydraulic station: hydraulic tank 20L, integrated with over-flow valve, safety valve, pressure gauge, discharge valve, electromagnetic valve, anti-shock pressure gauge, etc.

9) High pressure mixing head: developed by ourselves, high precision, hydraulic control, L type, self-clean, solvent free, life is more than 300 thousand times (if more than 300 thousand times, this head can be repaired and used again); Outer diameter of the nozzle: 24mm.

10) Temperature control system for tanks: the two tanks are heated by waters in the interlayer of the tanks; Equipped with two 2kW heaters; Electronic numeric displayer temperature controller is equipped to keep invariable temperature needed for glues.

11) Pressure pipes are chosen from Chinese domestic qualified supplier.

12) Auto-filling devices for two tanks: two self-absorbing pumps, motor power 1.5kW each.

13) Capacity of the tanks for polyurethane glue: 180 kg each

14) PLC automatic control: PLC programmable; Special PLC system from Chinese domestic which can save 99 programs.

15) Equipped piston type counting pump: adjusting accuracy 0.05%.

16) Generating pressure: 80-100MPa

17) Suspending arm length 2.5m, rotated in 270°, horizontal injecting or vertical injecting.

18) Dimension: Main body: about 1590 x 1200 x 2400mm

Tanks: 720 x 1550 x 2400mm

19) Weight: about 2500kg

Working Condition

| Main Parameters | ||||

| Raw materials | Mixing ratio in weight | Material temp,℃ | Viscosity (cps) | Density, (g/cm3) |

| Material A: polyol, foaming, agent, activator, equalizing agent, etc | 100 | 20-25 | <2000 | 1.1-1.4 |

| Material B:MDI-semi-prepolymer | 100-110 | 25-30 | 100-300 | 1.2 |

Model and Output Capacity

| Main Parameters | |||||

| NO | Items/ Model | SM20F-Y7 | SM20F-Y8 | SM20F-Y9 | SM20F-Y10 |

| 1 | Kg/min(g/s) Total pouring volume(kg/min)(kg/s) | 60-180(1-3) | 90-270(1.5-4.5) | 150-450(2.5-7.5) | 200-600(3.3-10) |

| 2 | Weight of product(kg) | 5-60 | 10-90 | 15-120 | 20-200 |

| 3 | Tank capacity(l) | 200 | 300 | 500 | 800 |

| 4 | r.p.m Revolving speed of blending(r.p.m) | 6300 | 6300 | 4000-6000 | 4000-6000 |

| 5 | Total power(kw) | 20 | 30 | 40 | 50 |

| 6 | Outline size, LxWxX(m) | 2.2x3 | 2.5x2.5x3 | 3x3x3.5 | 3.5x3.5x3.5 |

| 7 | Weight (kg) | 1200 | 1500 | 2000 | 2500 |

TallKee Steel Structure is a professional manufacturer and supplier of PU foam machine in China. Apart from low pressure polyurethane foam machine and high pressure polyurethane foam machine, we also offer EPS - rock wool sandwich panel machine like C purlin roll forming machine, Z purlin roll forming machine etc; auxiliary equipment products like automatic tube bending machine, plate bending machine etc; k-span machine, like automatic building machine, ultimate building machine and arch style buildings forming machine. With good quality and affordable price, the products produced by our company has exported Germany, Holland, India, Indonesia, New Zealand, Syria, United Arab Emirates, Russia, Kuwait, South Africa, and Bangladesh. If you are interested in our products, please contact us for details.

-

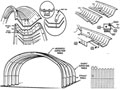

- K Span machine

The UBM ultimate k-span building machine, integrating advanced technology, can be controlled by microprocessor. This equipment ...

-

- Arch Building Forming Machine

1. The arch style buildings forming machine from TallKee Company, is also called arch steel buildings. It has a better performance of durability, ...